Adhesives for wafer cutting

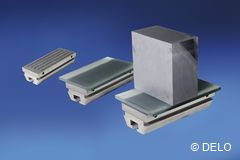

The increasing cost pressure on the photovoltaics market means that production processes must be optimized continuously. DELO’s two-component RM compounds (ReMovables) are precisely tailored to the high requirements in the wafering process, and therefore make possible high output rates. To prepare the cutting process, the assembly plate, the loss plate or carrier, and the silicon ingots are bonded and fixed.

During wafering, the bonded silicon ingots are clamped into the wire saw by means of the assembly plate. Then they are cut into thin wafers. The adhesive must reliably fix the cut wafers to the loss plate. Afterwards, the wafers must be debonded from the loss plate without leaving any residue, for example, in baths of hot water or diluted acid. The adhesive must not contaminate the debonding bath or the silicon, but should adhere to the carrier.

Properties

- Nonylphenol-free

- High temperature stability and high bond strength on silicon, glass, polymer, steel, or aluminum

- Excellent resistance to glycol (slurry)

- Universal debonding in annealed media like water or diluted acids without leaving any residue

Advantages

- Excellent sawing properties for slurry and diamond wire saws

- Reliable fixing during cutting and very low silicon waste

- High process reliability

- Processing times and curing times tailored to the process

- No contamination of the silicon material during debonding

Contacting of thin-film cells

Contacting of thin-film cells by conductive adhesives is a gentle conducting method and has numerous advantages over conventional methods like soldering and ultrasonic welding. The maximum curing temperature of the adhesives is +150 °C, which is significantly lower than the temperature during soldering.

The adhesives’ tension-equalizing properties prevent mechanical tensions and reduce micro cracks and cell failure. DELO supplies customized products for various variants of thin-film modules.

Properties

- One-component and heat-curing

- 100 % solvent-free

- Easy handling and dispensing

- Fast curing

- Long processing time

- Reliable and permanent contacting

- Optimized for a wide variety of thin-film surfaces and structures (rigid, flexible)

Advantages

- Easy to integrate into existing production processes

- Reduction of the cycle time by single shot process option (lamination and adhesive curing in one step)

- Flexible material selection

Please select an adhesive on the left side or complete the inquiry form below or call us

at +31 575 462025