Die attach

Die attach adhesives in leadframe packages require a high temperature resistance for lead-free soldering processes, good electrical and thermal properties, and the possibility of low-tension curing. DELO has adapted its products to exactly meet these requirements.

Possibilities of use

- Semiconductor leadframe products

- Die attach with low Young’s modulus for MEMS packages

- Die attach for organic substrates

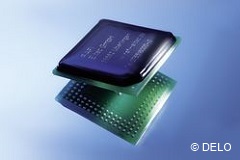

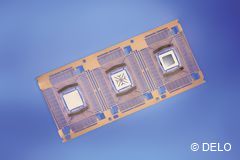

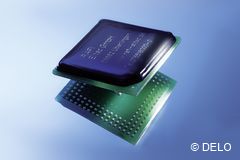

Encapsulants for the chip-on-board (COB) technology

RAFI Eltec GmbH, Überlingen, Germany, uses the DELOMONOPOX anhydrides as Dam&Fill. For the assembly, solder deposits are attached to the bottom in the form of BGA ballings, followed by one-side SMD assembly. The SMD assemblies produced are subsequently Dam&Fill-encapsulated.

In this method, two beads of adhesive are circumferentially dispensed as “Dam” on top of each other, which are subsequently “Fill”-ed. For this purpose, a screw dispensing valve is used in order to ensure that the components are evenly dispensed. Afterwards, the components are laser-marked on the encapsulation that has been cured in an air convection oven at +150 °C for 20 min.

Adhesive processing is reliable, and planar, large-area encapsulation geometries are possible. In addition, the adhesive fulfills all requirements on solder resistance. The dispensing profile can easily be adjusted to the specific package geometry, enabling high flexibility in production. It also gives a very homogeneous processing behavior, protects the component resp. the sensitive electronic parts from environmental influences, and performs excellently in reliability qualification tests. The material’s properties minimize the stress in the package. Thanks to the planar encapsulation, the component can be assembled just like a BGA module.

Sealing of sensors

The new anhydrides have proven successful in practice. These products are used in oil pressure sensors in cars. They cast the inside of the sensor and also seal the electrodes.

In comprehensive stress tests, the sensors casted with DELOMONOPOX proved to be completely tight. The tests included long-term storage at +150 °C, storage in ATF oil at +150 °C for 1000 h, 1000 cycles temperature shock at -40 / +150 °C, the VDA climate test, as well as customer-specific vibration tests and mechanical shock tests.

Please select an adhesive on the left side or complete the inquiry form below or call us

at +31 575 462025