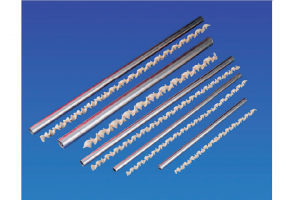

The SM Series stainless steel tube mixers are suited for mixing two-component reactive resin systems. These durable stainless steel mixers consist of alternating left and right hand helical elements, which are nickel brazed within the entire length of the tubular mixer housing. The mixer has to be cleaned immediately after use and it is recommended to briefly flush it with the main component only and then with a mixture of solvent/air. If partial or complete hardening of the components occurs, it can be burned out at 500º to 600º C.

| Material | Housing: Stainless steel 1.4571 Elements: Stainless steel 1.4404 or 1.4435 |

| Number of Elements | 24 or 30 |

| Retention of elements | Brazed with nickel base alloy over entire length of element assembly |

| End Connectors | Plain end |

| Max. Operating Temperature |

Max. allowable operating pressure (see table below) according to DIN 2413, scope of application 1, permanent elongation limit 1% at 20ºC, safety factor 1.7 |

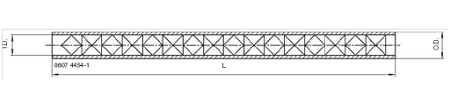

| Tolerances | O.D. and wall: According to DIN 2391, page 1: Length +/- 1mm |

|

Part Numbers |

Inside |

Number of Elements |

Outside |

Length L (mm) |

Max. |

|

SM 03-06-24 |

3 |

24 |

6 |

154 |

700 |

|

SM 04-06-24 |

4 |

24 |

6 |

148 |

467 |

|

SM 04-06-30 |

4 |

30 |

6 |

184 |

467 |

|

SM 05-08-24 |

5 |

24 |

8 |

185 |

525 |

|

SM 05-08-30 |

5 |

30 |

8 |

230 |

525 |

|

SM 06-08-24 |

6 |

24 |

8 |

221 |

350 |

|

SM 06-08-30 |

6 |

30 |

8 |

275 |

350 |

|

SM 08-10-24 |

8 |

24 |

10 |

294 |

280 |

|

SM 08-10-30 |

8 |

30 |

10 |

366 |

280 |

|

SM 10-14-24 |

10 |

24 |

14 |

368 |

400 |

|

SM 10-14-30 |

10 |

30 |

14 |

458 |

400 |

|

SM 11-14-24 |

11 |

24 |

14 |

416 |

300 |

|

SM 11-14-30 |

11 |

30 |

14 |

518 |

300 |

|

SM 12-16-24 |

12 |

24 |

16 |

440 |

350 |

|

SM 12-16-30 |

12 |

30 |

16 |

548 |

350 |

|

SM 15-20-24 |

15 |

24 |

20 |

550 |

350 |

|

SM 15-20-30 |

15 |

30 |

20 |

685 |

350 |

|

SM 20-25-24 |

20 |

24 |

25 |

730 |

280 |

|

SM 20-25-30 |

20 |

30 |

25 |

910 |

280 |

|

SM 25-30-24 |

25 |

24 |

30 |

922 |

233 |

|

SM 25-30-30 |

25 |

30 |

30 |

1150 |

233 |