Static mixers are available a many variants, which do you need?

We offer a large selection of static mixers in different mixing geaometries and differnet sizes.

Below the explenation of reading our article code, with an example of the mixer MAH 05-13T.

MAH 05-13T

The first character of a Sulzer product:

A = Cartridges

D = Dispenser

M = Mixer

Conclusion: MAH 05-13T ? it is a “Mixer”

MAH 05-13T

The second character (of a mixer) tells someting about the useability:

Conclusion: MAH 05-13T ? It is suitable for a “cartridge 50ml”

MAH 05-13T

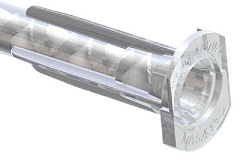

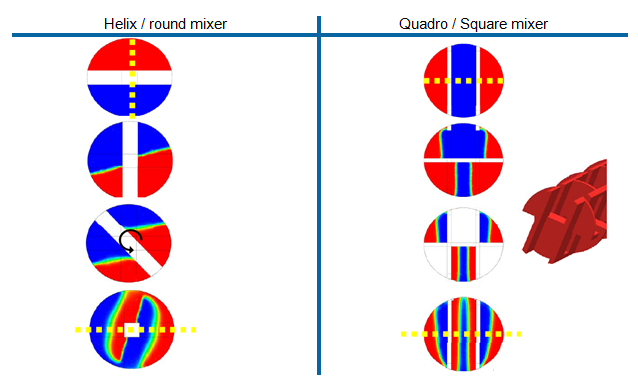

The third character (of a mixer) tells someting about the shape:

There is a different way of mixing between the helix (MIXPACTM) and quadro (QUADROTM) mixers. Some adhesive (technical properties of the adhesive) have a better mix quality with the round mixers and other adhesives have a better mix quality with the square mixers. We can’t tell you which is best, you have to test it with your adhesives.

Conclusion: MAH 05-13T ? It is a Helix (round) mixer.

MAH 05-13T

The fourth character (of a mixer) tells someting about the mixing ratio:

“no character” = ratio 1:1 or 2:1

“x” = ratio 4:1 or 10:1

Conclusion: MAH 05-13T mixer has no “x” this mixer is suitable for ratio 1:1 or 2:1

MAH 05-13T

The fifth character (of a mixer) tells someting about the inside diamter:

Conclusion: MAH 05-13T mixer has has an inside diameter of 5mm.

MAH 05-13T

The sixt character (of a mixer) tells someting about the amount of mixing elements:

Conclusion: MAH 05-13T mixer has 13 elements.

MAH 05-13T

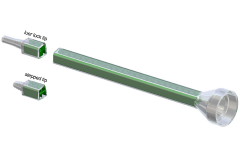

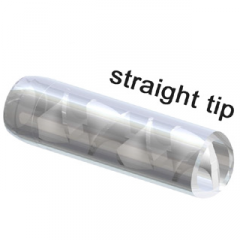

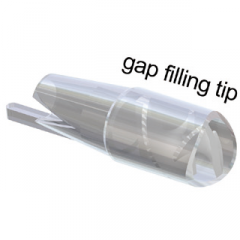

The last last character tells information about the end of the mixer:

Conclusion: MAH 05-13T has an stepped tip.

Another example:

MS 13-32T

M= Mixer

S = machine mixing with an bell mouth from 16,7mm (yellow)

13 = inner diameter of 13mm

32 = 32 elements

T = stepped tip

This all-plastic assembly is ideal for messy or short pot life adhesives. Its low cost allows disposal of the mixer instead of purging or burning. The housing is transparent, so the operator can inspect the condition of the mixer. With the interior mixing elements molded of Acetal (polymer coated cellulose fiber), it has the toughness and chemical resistance to be completely inert to all common solvents. Maximum Service temperature is 250° F (121° C).

Specification

Elements: Acetal, non-removable

Housing: Nylon or nylon with brass threaded ends

| Part Numbers | Inside Dia. (mm) | Number of elements | Outside Dia. (mm) | Length (mm) | Nozzle Dia. (mm) | Replacement Siko Part No. |

| Nordson 7700626 - TAH 140-230 | 2.39 | 30 | 4.75 | 82.6 | Plain | Please contact us |

| Nordson 7700632 - TAH 140-324 | 3.18 | 24 | 4.75 | 55.9 | Plain | Please contact us |

| Nordson 7700634 - TAH 140-330 | 3.18 | 30 | 4.75 | 88.9 | Plain | Please contact us |

| Nordson 7700635 - TAH 140-360 | 3.18 | 60 | 4.75 | 88.9 | Plain | Please contact us |

| Nordson 7700639 - TAH 140-424 | 4.80 | 24 | 6.35 | 104.1 | Plain | Please contact us |

| Nordson 7700641 - TAH 140-432 | 4.80 | 32 | 6.35 | 137.2 | Plain | Please contact us |

| Nordson 7700647 - TAH 140-624 | 6.30 | 24 | 9.53 | 165.1 | Plain | Please contact us |

| Nordson 7700650 - TAH 140-632 | 6.30 | 32 | 9.53 | 215.9 | Plain | Please contact us |

| Nordson 7700653 - TAH 140-640 | 6.30 | 40 | 9.53 | 266.7 | Plain | Please contact us |

| Nordson 7700654 - TAH 140-648 | 6.30 | 48 | 9.53 | 215.9 | Plain | Please contact us |

| Nordson 7700655 - TAH 140-656 | 6.30 | 56 | 9.53 | 215.9 | Plain | Please contact us |

| Nordson 7700659 - TAH 140-812 | 9.32 | 12 | 12.70 | 111.8 | Plain | Please contact us |

| Nordson 7700661 - TAH 140-824 | 9.32 | 24 | 12.70 | 213.4 | Plain | Please contact us |

| Nordson 7700662 - TAH 140-830 | 9.32 | 30 | 12.70 | 264.2 | Plain | Please contact us |

| Nordson 7700663 - TAH 140-836 | 9.32 | 36 | 12.70 | 315.0 | Plain | Please contact us |

| Nordson 7700664 - TAH 140-842 | 9.32 | 42 | 12.70 | 365.8 | Plain | Please contact us |

| Nordson 7700702 - TAH 145-712 | 8.00 | 12 | 11.10 | 180.3 | 1/4” | Please contact us |

| Nordson 7700703 - TAH 145-718 | 8.00 | 18 | 11.10 | 231.1 | 1/4” | Please contact us |

| Nordson 7700704 - TAH 145-724 | 8.00 | 24 | 11.10 | 271.8 | 1/4” | Please contact us |

| Nordson 7700705 - TAH 145-730 | 8.00 | 30 | 11.10 | 322.6 | 1/4” | Please contact us |

| Nordson 7700711 - TAH 145-812 | 9.40 | 12 | 12.70 | 190.5 | 1/4” | Please contact us |

| Nordson 7700712 - TAH 145-818 | 9.40 | 18 | 12.70 | 243.8 | 1/4” | Please contact us |

| Nordson 7700713 - TAH 145-824 | 9.40 | 24 | 12.70 | 292.1 | 1/4” | Please contact us |

| Nordson 7700715 - TAH 145-830 | 9.40 | 30 | 12.70 | 342.9 | 1/4” | Please contact us |

| Nordson 7700737 - TAH 146-212 | 12.62 | 12 | 16.00 | 215.9 | 3/8” | Please contact us |

| Nordson 7700738 - TAH 146-218 | 12.62 | 18 | 16.00 | 281.9 | 3/8” | Please contact us |

| Nordson 7700739 - TAH 146-224 | 12.62 | 24 | 16.00 | 342.9 | 3/8” | Please contact us |

| Nordson 7700741 - TAH 146-230 | 12.62 | 30 | 16.00 | 406.4 | 3/8” | Please contact us |

| Nordson 7700754 - TAH 146-410 | 16.00 | 10 | 19.05 | 238.8 | 1/2” | Please contact us |

| Nordson 7700755 - TAH 146-420 | 16.00 | 20 | 19.05 | 365.8 | 1/2” | Please contact us |

| Nordson 7700757 - TAH 146-430 | 16.00 | 30 | 19.05 | 500.4 | 1/2” | Please contact us |

| Nordson 7700760 - TAH 146-435 | 16.00 | 35 | 19.05 | 563.9 | 1/2” | Please contact us |

| Nordson 7700769 - TAH 146-608 | 19.91 | 8 | 23.37 | 254.0 | 3/4” | Please contact us |

| Nordson 7700770 - TAH 146-616 | 19.91 | 16 | 23.37 | 383.5 | 3/4” | Please contact us |

| Nordson 7700773 - TAH 146-624 | 19.91 | 24 | 23.37 | 518.2 | 3/4” | Please contact us |

| Nordson 7700776 - TAH 146-632 | 19.91 | 32 | 23.37 | 650.2 | 3/4” | Please contact us |

The 160 serie products are used for dispensing epoxy and other two-part reactive materials with meter-mix-dispense (MMD) equipment. With conventional meter/mix manifolds the reactive materials meet within the manifold before the mixer. If the materials are allowed to gel the manifold will plug and must be disassembled. This can be a time-consuming and expensive task. The Series 160 eliminates this problem. The mixing nozzle has an oversized bell inlet. Manifolds and valves separately port the A and B materials directly into the mixer. Cleanup simply involves removing the mixer and wiping the manifold face clean. A metal jacket is recommended if the working pressure inside the mixing nozzle exceeds 150 psi (10 bar).

Specification

Element: Acetal

Housing: Polypropylene

| Part Numbers | Inside Dia. (mm) | Number of elements | Outside Dia. (mm) | Length (mm) | Nozzle Dia. (mm) | Replacement Siko Part No. |

| Nordson 7700810 - TAH 160-408SH | 4.80 | 8 | 7.62 | 66.5 | Slip luer | MS 05-24T |

| Nordson 7026047 - TAH 160-408LL | 4.80 | 8 | 7.62 | 66.5 | Luer lock | MS 05-24T |

| Nordson 7700811 - TAH 160-416 | 4.80 | 16 | 7.62 | 99.1 | Slip luer | MS 05-24T |

| Nordson 7700819 - TAH 160-424SH | 4.80 | 24 | 7.62 | 131.6 | Slip luer | MS 05-24T |

| Nordson 7700817 - TAH 160-424LL | 4.80 | 24 | 7.62 | 131.6 | Luer lock | MS 05-24T |

| Nordson 7700824 - TAH 160-432SH | 4.80 | 32 | 7.62 | 164.6 | Slip luer | MS 05-32T |

| Nordson 7700822 - TAH 160-432LL | 4.80 | 32 | 7.62 | 164.6 | Luer lock | MS 05-32T |

| Nordson 7700825 - TAH 160-448 | 4.80 | 48 | 7.62 | 229.6 | Slip luer | MS 05-32T |

| Nordson 7700826 - TAH 160-448LL | 4.80 | 48 | 7.62 | 229.6 | Luer lock | MS 05-32T |

| Nordson 7700830 - TAH 160-608SH | 6.30 | 8 | 9.40 | 90.4 | Slip luer | MS 05-32T |

| Nordson 7700829 - TAH 160-608LL | 6.30 | 8 | 9.40 | 90.4 | Luer lock | MS 06-24T |

| Nordson 7700831 - TAH 160-616 | 6.30 | 16 | 9.40 | 137.8 | Slip luer | MS 06-24T |

| Nordson 7700834 - TAH 160-616LL | 6.30 | 16 | 9.40 | 137.8 | Luer lock | MS 06-24T |

| Nordson 7700837 - TAH 160-624 | 6.30 | 24 | 9.40 | 189.5 | Slip luer | MS 06-24T |

| Nordson 7700850 - TAH 160-624LL | 6.30 | 24 | 9.40 | 189.5 | Luer lock | MS 06-24T |

| Nordson 7700856 - TAH 160-632 | 6.30 | 32 | 9.40 | 241.0 | Slip luer | MS 06-32T |

| Nordson 7700862 - TAH 160-632LL | 6.30 | 32 | 9.40 | 241.0 | Luer lock | MS 06-32T |

| Nordson 7700864 - TAH 160-632RTLL | 6.30 | 32 | 9.40 | 241.0 | Luer lock | MS 06-32T |

| Nordson 7700866 - TAH 160-648 | 6.30 | 48 | 9.40 | 333.8 | Slip luer | MS 06-48T |

| Nordson 7700872 - TAH 160-648LL | 6.30 | 48 | 9.40 | 333.8 | Luer lock | MS 06-48T |

| Nordson 7704018 - TAH 160-648LLX | 6.30 | 48 | 9.40 | 333.8 | Luer lock | MS 06-48T |

| Nordson 7700873 - TAH 160-718 | 8.00 | 18 | 11.71 | 176.8 | Stepped | MS 08-24T |

| Nordson 7700875 - TAH 160-718LL | 8.00 | 18 | 11.71 | 176.8 | Luer lock | MS 08-24T |

| Nordson 7700876 - TAH 160-724 | 8.00 | 24 | 11.71 | 224.5 | Stepped | MS 08-24T |

| Nordson 7700878 - TAH 160-724LL | 8.00 | 24 | 11.71 | 224.5 | Luer lock | MS 08-24T |

| Nordson 7700879 - TAH 160-732 | 8.00 | 32 | 11.71 | 290.6 | Stepped | MS 08-32T |

| Nordson 7700882 - TAH 160-732LL | 8.00 | 32 | 11.71 | 290.6 | Luer lock | MS 08-32T |

| Nordson 7700885 - TAH 160-812 | 9.30 | 12 | 12.95 | 139.2 | Stepped | MS 10-18T |

| Nordson 7700892 - TAH 160-812LL | 9.30 | 12 | 12.95 | 139.2 | Luer lock | MS 10-18T |

| Nordson 7013510 - TAH 160-818 | 9.30 | 18 | 12.95 | 184.9 | Stepped | MS 10-18T |

| Nordson 7700902 - TAH 160-818LL | 9.30 | 18 | 12.95 | 184.9 | Luer lock | MS 10-18T |

| Nordson 7700904 - TAH 160-824 | 9.30 | 24 | 12.95 | 232.4 | Stepped | MS 10-24T |

| Nordson 7700924 - TAH 160-824LL | 9.30 | 24 | 12.95 | 232.4 | Luer lock | MS 10-24T |

| Nordson 7700927 - TAH 160-830 | 9.30 | 30 | 12.95 | 285.5 | Stepped | MS 10-32T |

| Nordson 7700931 - TAH 160-830LL | 9.30 | 30 | 12.95 | 285.5 | Luer lock | MS 10-32T |

| Nordson 7700932 - TAH 160-840 | 9.30 | 40 | 12.95 | 359.2 | Stepped | MS 10-32T |

| Nordson 7700939 - TAH 160-840LL | 9.30 | 40 | 12.95 | 359.2 | Luer lock | MS 10-32T |

| Nordson 7700932 - TAH 160-860 | 9.30 | 60 | 12.95 | 569.0 | Stepped | MS 10-32T |

| Nordson 7700939 - TAH 160-864 | 9.30 | 64 | 12.95 | 609.6 | Stepped | MS 10-32T |

| Nordson 7700990 - TAH 161-212 | 12.65 | 12 | 16.76 | 170.4 | Stepped | MS 13-24T |

| Nordson 7700995 - TAH 161-212LL | 12.65 | 12 | 16.76 | 170.4 | Luer lock | MS 13-24T |

| Nordson 7701001 - TAH 161-218 | 12.65 | 18 | 16.76 | 230.6 | Stepped | MS 13-24T |

| Nordson 7701007 - TAH 161-218LL | 12.65 | 18 | 16.76 | 230.6 | Luer lock | MS 13-24T |

| Nordson 7701010 - TAH 161-224 | 12.65 | 24 | 16.76 | 294.6 | Stepped | MS 13-24T |

| Nordson 7701025 - TAH 161-224LL | 12.65 | 24 | 16.76 | 294.6 | Luer lock | MS 13-24T |

| Nordson 7701028 - TAH 161-230 | 12.65 | 30 | 16.76 | 357.9 | Stepped | MS 13-32T |

| Nordson 7701035 - TAH 161-230LL | 12.65 | 30 | 16.76 | 357.9 | Luer lock | MS 13-32T |

| Nordson 7701038 - TAH 161-236 | 12.65 | 36 | 16.76 | 422.4 | Stepped | MS 13-32T |

| Nordson 7701042 - TAH 161-236LL | 12.65 | 36 | 16.76 | 422.4 | Luer lock | MS 13-32T |

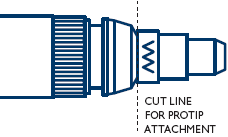

The Series 160A mixing nozzle accepts ProTips and, thus, combines the design benefits of the disposable Series 160 static mixer with the advantage of flexibility in adhesive dispensing. These mixers have the “A” tip which allows the user to either mix and apply adhesive in a single small bead or, by attaching the ProTip, dispense material in a wide variety of widths. A metal jacket is recommended when the working pressure inside the nozzle exceeds 150 psi (10 bar).

Specification

Element: Acetal

Housing: Polypropylene

| Part Numbers | Inside Dia. (mm) | Number of elements | Outside Dia. (mm) | Length (mm) | Nozzle Dia. (mm) | Replacement Siko Part No. |

| TAH 160A-718 | 8.00 | 18 | 11.71 | 176.8 | ProTip | please contact us |

| TAH 160A-724 | 8.00 | 24 | 11.71 | 224.5 | ProTip | please contact us |

| TAH 160A-818 | 9.30 | 18 | 12.95 | 184.9 | ProTip | please contact us |

| TAH 160A-824 | 9.30 | 24 | 12.95 | 232.4 | ProTip | please contact us |

| TAH 161A-218 | 12.65 | 18 | 19.76 | 230.6 | ProTip | please contact us |

| TAH 161A224 | 12.65 | 24 | 16.76 | 249.6 | ProTip | please contact us |

| Part Numbers | Style | Description | Width | Replacement Siko Part No. |

| TAH 163A-01 | Ribbon | ProTip | 12.70 | please contact us |

| TAH 163A-02 | Ribbon | ProTip | 25.40 | please contact us |

| TAH 163A-03 | Ribbon | ProTip | 43.18 | please contact us |

| TAH 163A-06 | Half round | ProTip | 12.70 | please contact us |

| TAH 163A-07 | Half round | ProTip | 25.40 | please contact us |

| TAH 163A-05 | Transitional | 1/4“ female NPT | n.a. | please contact us |

| TAH 163A-08 | Transitional | 45º Elbow | n.a. | please contact us |

| TAH 163A-09 | Transitional | female luer adapter | n.a. | please contact us |

| TAH 163A10 | Transitional | 1“ - 2“ edge guide | n.a. | please contact us |

The 160AA Quick Spray series is a low-pressure air-assisted spray system for two-component coatings. This disposable static mixer is designed for use with conventional meter/mix equipment or with two-component cartridge system. The reactive coating is mixed within the disposable static mixer. At the mixer outlet, air is introduced which atomizes the liquid stream. The degree of atomization can be adjusted by regulating the airflow rate. Since the reactive coating is contained completely within the mixer, cleanup is minimal.

The 160AA Quick Spray series is a low-pressure air-assisted spray system for two-component coatings. This disposable static mixer is designed for use with conventional meter/mix equipment or with two-component cartridge system. The reactive coating is mixed within the disposable static mixer. At the mixer outlet, air is introduced which atomizes the liquid stream. The degree of atomization can be adjusted by regulating the airflow rate. Since the reactive coating is contained completely within the mixer, cleanup is minimal.

| Part Numbers | Inside Dia. (mm) | Number of elements | Max. Pressure (bar) | Replacement Siko Part No. |

| Nordson 7700846 - TAH 160-624AA-4 | 6.30 | 24 | 25 | MixCoat system |

| Nordson 7700920 - TAH 160-824AA-2 | 9.30 | 24 | 21 | MixCoat system |

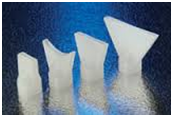

Intended for high flow rate meter mix applications, this series contains our largest disposable mixing elements—0.784 inches in diameter with 16 to 48 elements. The rugged Nylon housing has an oversized bell inlet. The downstream outlet is designed to accept the Pro Tip™ accessories or use the 1/2″ NPS male thread to attach extensions or other types of accessories.

Specification

Element: Acetal

Housing: Nylon

| Part Numbers | Inside Dia. (mm) | Number of elements | Outside Dia. (mm) | Length (mm) | Nozzle Dia. (mm) | Replacement Siko Part No. |

| Nordson 7701057 - TAH 162A-616 | 19.90 | 16 | 24.90 | 317 | n.a. | Siko 20-16 |

| Nordson 7701059 - TAH 162A-623 | 19.90 | 23 | 24.90 | 432 | n.a. | Siko 20-23 |

| Nordson 7701063 - TAH 162A-632 | 19.90 | 32 | 24.90 | 622 | n.a. | Siko 20-32 |

| Nordson 7701066 - TAH 162A-639 | 19.90 | 39 | 24.90 | 770 | n.a. | Siko 20-39 |

| Nordson 7701067 - TAH 162A-648 | 19.90 | 48 | 24.90 | 925 | n.a. | Siko 20-48 |

| Part Numbers | Style | Description | Width | Replacement Siko Part No. |

| TAH 163A-01 | Ribbon | ProTip | 12.70 | please contact us |

| TAH 163A-02 | Ribbon | ProTip | 25.40 | please contact us |

| TAH 163A-03 | Ribbon | ProTip | 43.18 | please contact us |

| TAH 163A-06 | Half round | ProTip | 12.70 | please contact us |

| TAH 163A-07 | Half round | ProTip | 25.40 | please contact us |

| TAH 163A-05 | Transitional | 1/4“ female NPT | n.a. | please contact us |

| TAH 163A-08 | Transitional | 45º Elbow | n.a. | please contact us |

| TAH 163A-09 | Transitional | female luer adapter | n.a. | please contact us |

| TAH 163A10 | Transitional | 1“ - 2“ edge guide | n.a. | please contact us |

Featuring a standard Bayonet connection, the Series 190 mixer is designed for use with 50mL two-component cartridges. Typical applications include mixing epoxies, urethanes, acrylics, and silicones. The Series 190 has five diameters available with four outlet styles: Slip Luer, Full Bore, H-Tapered, and Stepped. The Slip Luer is our standard offering. The Full Bore ensures maximum flow with minimal back pressure. The H-Tapered outlet is offered where precise placement of the adhesives is required.

Featuring a standard Bayonet connection, the Series 190 mixer is designed for use with 50mL two-component cartridges. Typical applications include mixing epoxies, urethanes, acrylics, and silicones. The Series 190 has five diameters available with four outlet styles: Slip Luer, Full Bore, H-Tapered, and Stepped. The Slip Luer is our standard offering. The Full Bore ensures maximum flow with minimal back pressure. The H-Tapered outlet is offered where precise placement of the adhesives is required.

| Part Numbers | Inside Dia. (mm) | Number of elements | Length (mm) | Nozzle Dia. (mm) | Replacement Siko Part No. |

| Nordson 7701408 - TAH 190-212 | 2.36 | 12 | 38 | Slip Luer | MAH 03-13S |

| Nordson 7701411 - TAH 190-312H | 3.18 | 12 | 53 | H Tapered | MAH 03-13S |

| Nordson 7701416 - TAH 190-324H | 3.18 | 24 | 86 | H Tapered | MAH 03-17S |

| Nordson 7701417 - TAH 190-408BT | 4.75 | 8 | 41 | Full Bore | MAH 04-13S |

| Nordson 7701424 - TAH 190-416 | 4.75 | 16 | 86 | Slip Luer | MAH 04-17S |

| Nordson 7701436 - TAH 190-416H | 4.75 | 16 | 86 | H Tapered | MAH 04-17S |

| Nordson 7701438 - TAH 190-507 | 5.40 | 7 | 58 | Slip Luer | MAH 05-07T |

| Nordson 7701449 - TAH 190-517-01 | 5.40 | 17 | 112 | Stepped | MAH 05-17T |

| Nordson 7701453 - TAH 190-521-01 | 5.40 | 21 | 135 | Stepped | MAH 05-21T |

| Nordson 7701458 - TAH 190-612 | 6.35 | 12 | 99 | Slip Luer | MAH 06-12T |

| Nordson 7701486 - TAH 190-616-01 | 6.35 | 16 | 122 | Stepped | MAH 06-17T |

| Nordson 7701487 - TAH 190-620 | 6.35 | 20 | 150 | Slip Luer | MAH 06-21L |

| Nordson 7701488 - TAH 190-620-01 | 6.35 | 20 | 150 | Stepped | MAH 06-21T |

| Nordson 7701510 - TAH 190-620H | 6.35 | 20 | 150 | H Tapered | MAH 06-21T |

| Nordson 7701507 - TAH 190-620BT | 6.35 | 20 | 135 | Full Bore | MAH 06-21T |

Our Series 260 Spiral Mixers with Integral Nut inlet connections.

Specification

Elements: Polypropylene

Housing: Polypropylene

| Part Numbers | Inside Dia. (mm) | Number of elements | Length (mm) | Nozzle Dia. (mm) | Replacement Siko Part No. |

| Nordson 7701749 - TAH 261-212 | 12.8 | 12 | 170 | Stepped | MGQ 10-10A-02 |

| Nordson 7701758 - TAH 261-218 | 12.8 | 18 | 231 | Stepped | MGQ 10-16A |

| Nordson 7701770 - TAH 261-224 | 12.8 | 24 | 297 | Stepped | MGQ 10-16A |

| Nordson 7701759 - TAH 261-218BL | 12.8 | 18 | 358 | Barb Ext | KMGQ 14-20E |

| Nordson 7701742 - TAH 260N-805 | 9.3 | 5 | 124 | Tapered | MGQ 10-14A |

| Nordson 7701745 - TAH 260N-812T | 10.5-8.5 | 12 | 218 | Tapered | MGQ 10-14A |

| Nordson 7701782 - TAH 261AN-218 | 12.8 | 18 | 244 | Stepped | MGQ 10-19A |

| Nordson 7701795 - TAH 261N-218BL | 12.8 | 18 | 365 | Barb Ext | KMGQ 14-20E |

| Nordson 77018042 - TAH 62-616-01 | 20.0 | 16 | 327 | Full Bore | MGQ 14-20 |

| Nordson 7701806 - TAH 262-620-01 | 20.0 | 20 | 396 | Full Bore | MGQ 14-20 |

The disposable static mixer is a product that ensures superior mixing performance and allows the operator to be closer to the work piece. The square geometry consists of a series of alternating left- and right-hand elements with intermittent flow inverters which effectively channel the fluids from the walls into the center of the mixer and from the center to the walls.

Specification

Elements: Acetal

Housing: Polypropylene

| Part Numbers | Inside Dia. (mm) | Number of elements | Length (mm) | Inlet | Replacement Siko Part No. |

| Nordson 7701353 - TAH 180A-818 | 8.7 | 18 | 130 | Bell | MCQ 08-24T |

| Nordson 7701358 - TAH 180A-824 | 8.7 | 24 | 160 | Bell | MCQ 08-24T |

| Nordson 7701367 - TAH 180A-836 | 8.7 | 36 | 244 | Bell | MCQ 08-32T |

| Nordson 7701370 - TAH 180AN-818 | 8.7 | 18 | 142 | Integral Nut | MGQ 08-18T |

| Nordson 7701385 - TAH 180AN-824 | 8.7 | 24 | 173 | Integral Nut | MGQ 08-24T |

| Nordson 7701393 - TAH 180AN-830 | 8.7 | 30 | 206 | Integral Nut | MGQ 08-24T |

| Nordson 7703998 - TAH 180AN-821NB | 8.7 | 21 | 142 | Integral Nut | MGQ 08-24T |

The Series 295 Turbo Mixer™ is a disposable static mixer which ensures superior mixing performance and allows the operator to be closer to the work piece. The Turbo (square) geometry consists of a series of alternating left- and right-hand elements with intermittent flow inverters. The flow inverters effectively channel the fluids from the walls into the center of the mixer and from the center to the walls.

Specification

Elements: Polypropylene

Housing: Polypropylene

| Part Numbers | Inside Dia. (mm) | Number of elements | Length (mm) | Nozzle Dia. (mm) | Replacement Siko Part No. |

| Nordson 7701830 - TAH 295-620 | 5.15 | 20 | 102 | Slip luer | MAQ 05-24L |

| Nordson 7701832 - TAH 295-620BT | 5.15 | 20 | 92 | Full bore | MAQ 05-24L |

| Nordson 7701836 - TAH 295-620LL | 5.15 | 20 | 102 | Luer Lock | MAQ 05-24L |